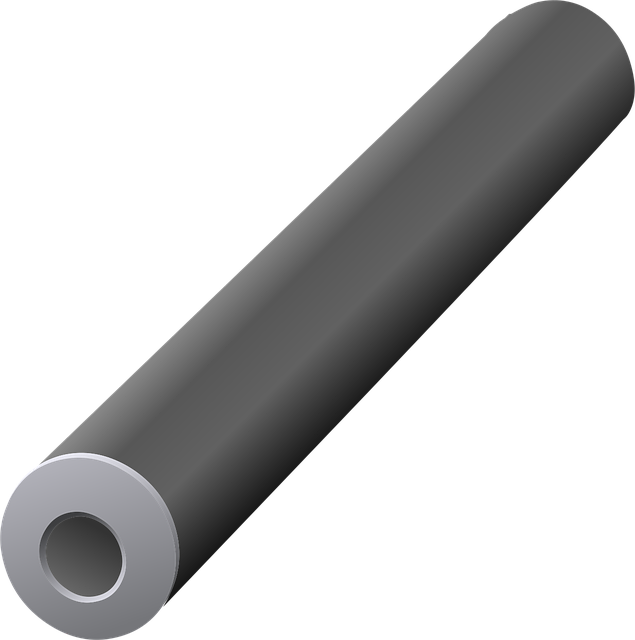

Trusted Steel Squares: Top Quality Suppliers for Albury Wodonga Projects

Jones Plumbing Plus is a trusted Steel Supplies Albury Wodonga provider known for its high-quality, durable steel square tubes that meet industry standards. With a robust network of reliable suppliers, they ensure consistent access to top-tier m…….